What is Abrasion Testing

When brooding about however quality could be a attribute that a lot of firms pride themselves on however while not intensive testing, does one skills long your product can last before breaking or carrying out?

The main reason why a corporation will abrasion testing after they are manufacturing a top quality product that’s error-free. it’s necessary to examine a material’s wear resistance.

This take a look at is performed by rubbing a fabric at an explicit weight and speed to see at that purpose the fabric begins to wear.

Abrasion testing will be utilized in many alternative industries and may be helpful for people who supply warranties. the subsequent ar the various sorts of tests.

- Two-body abrasive wear – once more durable fragments ar forced up against and stirred on a surface;

- slippy wear – happens between 2 solid objects and is generated from a back and forth movement;

- Mar abrasion – happens once constant distortions that haven’t cracked the surface of a coating, however appear to alter the looks of its surface;

- Rolling abrasion (or three-body-wear) – happens once abrasive particles or dust ar allowed to roll between the surface and a contacting substance. Knowing precisely once a product can ought to get replaced will assist you perceive your product.

Clothing firms take a look at bound areas like knees and elbows to see however long the material can last before it wears out whereas piece of furniture firms perform testing of seating product and bedding. it’s additionally mark to suit several alternative product like rubber, plastics, paper, metal, and paint.

It is necessary to observe Rub Testing for Print and to own sensible quality labels. Testing surfaces and parts could be a unending task, however the results offer you peace of mind that you just will defend your claims of durable product with technological internal control.

So, the new Dame Joan Sutherland 2000 Rub Tester is one amongst the highest leaders in abrasion testing. It will be mark and set to your specifications and utilized in your abrasion take a look at method. we’ve modified the rub tester to stay up with trendy demands.

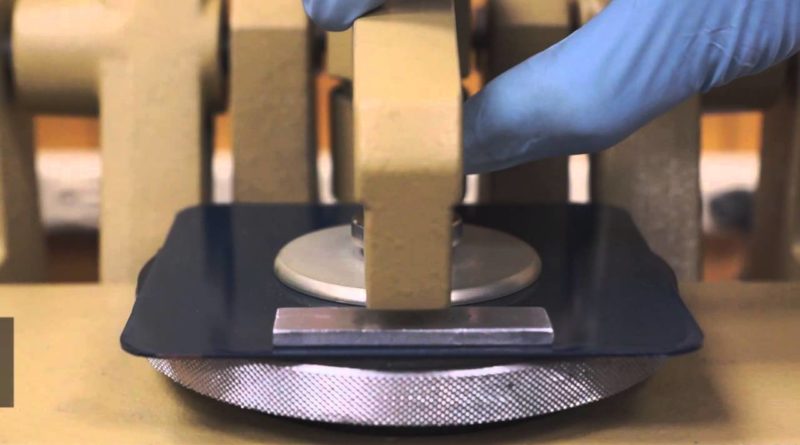

With extra speed controls and choices, it’s a product which will be utilized in other ways in an exceedingly quality assurance setting. Taber’s 2 fashionable choices embody the 5135 Rotary Abraser and 5750 Linear Abraser. The take a look at is performed employing a Taber Rotary Abraser by mounting a flat object to a turntable that rotates on a vertical axis at a collection speed.

The two Taber abrasive wheels ar applied with pressure, then down onto the surface. because the turntable rotates, rub-wear action is formed by contact of the take a look at object against the rotating 2 abrading wheels whereas a vacuum removes loose dust.

This testing edges nearly each business. it’s vital once testing high wear things like vinyl. World-wide or company standards and specifications facilitate to confirm that testing is performed in an exceedingly constant and consistent manner.

Furthermore, there has been outstanding work conducted developing take a look at procedures and lots of firms have a favourite tester that they use. it’s common for a producer involved concerning responsibility and products life to arouse correct simulation of the damage system.

A material creator trying to form the simplest product of wear-resistant materials might do an appropriate take a look at. Lastly, it’s necessary to raise inquiries to perceive the damage drawback and materials concerned once a client desires facilitate.